Living in a country like Pakistan we all know the summers can be really HOT and having a good working air conditioning system is not only luxury but it becomes necessary. Chiller ACs Chiller range cooling these are the best choice. We will discuss a few ways to search for deals on chiller air conditioners in Pakistan allowing you what maximum price of the best meets needs and get opportunities.

What is a Chiller AC?

In air conditioning, a chiller AC is an appliance that removes heat from a liquid via vapour-compression or absorption refrigeration cycle. This fluid can then be pumped through a heat exchanger to cool air or equipment as needed. These chilled water systems are mostly used in large commercial buildings and industrial facilities although they are sometimes combine with fan comics to provide total whole house or business cooling that has often been referred to as chiller ac.

Types of Chiller AC Systems

- Water-Cooled Chillers

- Air-Cooled Chillers

Each type has its own set of characteristics, advantages, and applications, which we will explore in detail.

Water-Cooled Chillers

The water-cooled chillers work by passing the refrigerant in a condenser, where heat is removed from the refrigeration and withdrawn again using cooling towers. The refrigerant absorbs this heat from the process water or air and is compressed to raise temperature (and create high pressure). The high-pressure, high-temperature refrigerant gas flows through a condenser and loses heat to water circulating through the evaporative section. The hot water is then pumped to a cooling tower where the air passing over it cools, and this nice comfortably chilled water returns back to your chiller… Now you repeat. This constant cycle is what enables water-cooled chillers to be so effective at large-scale cooling – absorbing heat, releasing it from the building and then reabsorbing more.

Air-Cooled Chillers

Air-cooled chillers remove the heat from the refrigerant by passing air over fins in a coil. The refrigerant is compressed to high pressure and temperature after it absorbs heat and vaporizes. This gas is then sent to condenser coils that are in the open air. These coils are designed to allow the maximum amount of heat from your refrigerant transfer into air that is blowing over them via fans. As the refrigerant does this, it releases its heat and condenses back into a liquid. This cooled refrigerant is then flowed back to absorb more heat, making air-cooled chillers perfect for jobs where water utilisation and chilly tower space are limited.

How Chillers Work

Understanding the functionality of chillers is crucial to appreciating their value. Let’s break down the process step-by-step:

The Chilling Process

Heat Absorption: The liquid (usually water) gives off heat that is absorbed by the chiller, using a refrigerant. It can be done by means of vapor-compression or absorption cycle.

Absorption: Heat absorbed by the refrigerant is driven off when water runs over the plates, transferring heat to be released elsewhere in equipment. This removes the heat from water in an efficient way.

Cooling Cycle: refrigerant is compressed at high pressure and at the same temperature then it cools down (it releases heat) After that expansion valves absorb to take back in from water. A secondary fluid absorbs the refrigerant in an absorption cycle and rejects heat.

Chilled Water Supply: The cold water is now transported through a heat exchanger where it cools the air or equipment as needed. This chilled water can be used in various applications, including air conditioning.

Conversion to Chiller AC

To convert the chilled water produced by a chiller into air conditioning, the system employs several components that work together to cool the air effectively throughout a building. Here’s a detailed explanation of the process:

Air Handler Units (AHUs)

Function: Air Handler Units (AHUs) – AHU distribute the air that is cooled in different parts of regions. When the chilled water is ready, it will be transported to AHUs by means of a pump. These have coils in it inside which the chilled water is flowing.

This is how the AHU uses these coils to cool the air. The cold air is distributed into the building.

Distribution: AHUs are usually found in vast commercial buildings or industrial facilities that require centralized air handling. They may be fitted with filters to sanitise the air before circulation.

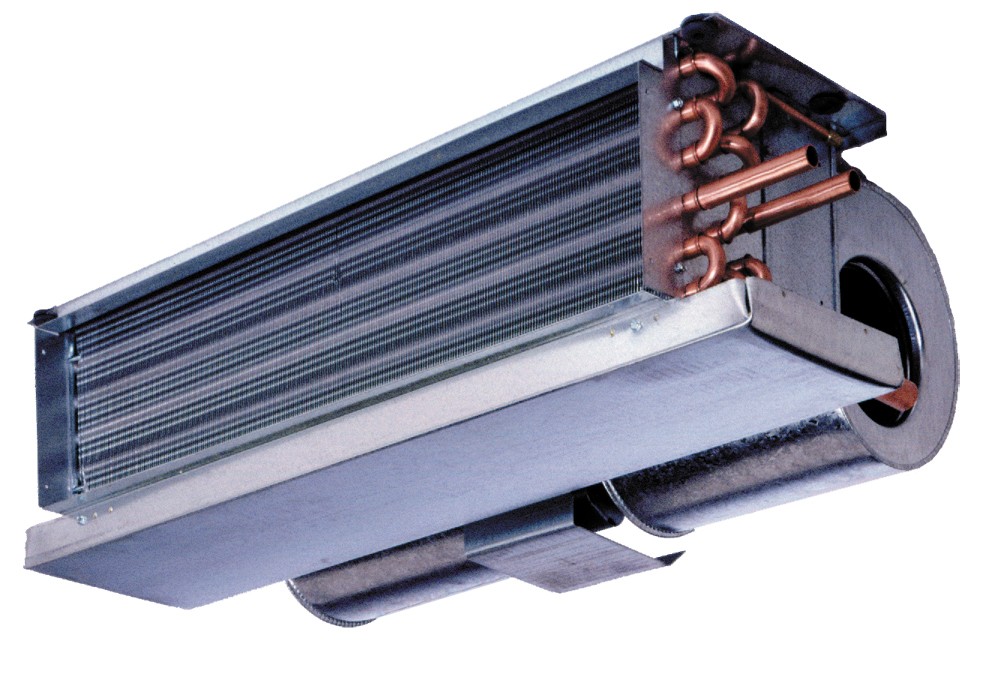

Fan Coil Units (FCUs)

Function: Some of the functions and features of AHUs are served by another type of equipment called Fan Coil Units or FCUs that are used mainly for cooling air in selected zones or in individual rooms. They also utilize cold water from the chiller system Cool air enters with cold water through a fan coil that is normally located at the supply air plenum.

Operation: In an FCU the chilled water circulates through a coil situated inside the unit. Air inside the FCU then flows over the cold coil and due to this the air also gets cooled. The cooled air is then directly supplied to the room or zone, as the case may be.

Flexibility: FCUs have zone control meaning that different areas in the building can have their own set temperatures. As such they are best suited for areas that do not require cooling during all times or periods that cool temperatures are required in limited measure.

Duct Systems

Function: Duct systems are for the distribution of the cooled air of AHUs or FCUs all over the building. They include a HVAC ducts system that distributes the conditioned air around the building from the air handling units.

Operation: Cooled air from AHU or FCU is supplied into this system after which it flows through a number of ducts to get to various rooms or zones. The ducts are intended to make sure that air is supplied to the required areas of the building with no exception.

Design Manufacturing: It is critically important that the duct system is well designed and installed correctly to prevent losses such as air leaks, temperature inconsistencies, and noise. Insulated ducts also tend to assist in maintaining the temperature of the transported air within the ducts.

Factors Affecting Chiller AC Prices in Pakistan

Several factors can influence the price of a chiller AC in Pakistan:

Brand and Quality: Renowned brands tend to be more expensive but offer better quality and reliability.

Capacity and Size: Larger units with higher cooling capacities will cost more than smaller units.

Energy Efficiency: More energy-efficient models may have a higher upfront cost but can save money in the long run through reduced energy bills.

Installation Costs: Professional installation is crucial for optimal performance, and these costs can vary based on the complexity of the installation.

Where to Find the Best Deals on Chiller ACs

You can find great deals on chiller ACs from various sources:You can find great deals on chiller ACs from various sources:

Authorized Dealers: Purchasing through these dealers is a good way to guarantee quality of products that are accompanied by warranties and after sales services.

Online Marketplaces: There is so much choice starting with the Daraz website and continuing with OLX, and others. Be an intelligent consumer, seek for offers, promos and reviews from other customers.

Local Retailers: Local appliance stores should be the next step; this way people can meet the units in person and possibly get more useful advice.

The Importance of Choosing the Right Supplier

Selecting a proper supplier means the reliable acquisition of a chiller Air Conditioning at the most favorable price. A reputable supplier offers:

Chillerhouse: Your Go-To Chiller Manufacturer

This is the reason why at Chiller house we ensured that our chillers include water cooled chillers and air cooled chillers are both of high quality and affordable. If you need a unit for commercial or for industrial use we can provide units to fit your required specification.

Customizable Solutions: It means that we can provide those solutions that are suitable for you. We are also provide solutions to your building depending on its cooling needs.

Competitive Pricing: For the consumption rates are fix sensibly, while maintaining a high quality and an attractive appearance.

Commitment to Quality: It is therefore our goal to offer long lasting and effective chillers models for today’s fast paced environment.

How to Choose the Right Chiller AC for Your Needs

Choosing the right chiller AC involves considering several factors:

Assessing Your Requirements

Cooling Needs: Working on the basis of the size of the area or the heat load. It is possible to determine the cooling capacity necessary for its cooling.

Budget: You should set your budget and then proceed to look at models. Make sure that are within that budget while fulfilling other needs.

Consulting with Experts

Professional Advice: Always talk to heating and cooling experts and get the advice on what will suit your specific needs.

Site Inspection: Consult with a professional to tell you the most suitable install arrangement when constructing your site.

Reading Reviews and Testimonials

Customer Feedback: Seek other buyer’s comments and feedback to determine the durability and efficiency of every model on the market.

Conclusion

Purchasing a chiller AC system in Pakistan involves the following factors in relation to the kind of chiller. Include water cooled chillers and air cooled chillers as well as energy efficient chillers. Overall factors such as total installed price. A more informed consumer will be able to find better deals for their cooling system. The most important is that create design according to given instruction or needs . At Chiller House, we pride ourselves in giving the best value for the money by delivering quality chiller systems. Choose your option of customization without compromise in quality, all within the best possible prices in the market.

FAQs

How long does a chiller AC last to be specifically useful in human life?

Chiller AC systems require proper maintenance and the useful life of this kind of air conditioning system is between fifteen to twenty years.

How cost efficient is a chiller AC in terms of saving energy hence cutting down power bills?

Chiller ACs are energy efficient, often lowering your energy costs between 20 to 30 percent than conventional air conditioning systems.

Are chiller ACs noisy?

Today, models of chiller AC are very quiet, but noise depends on the type of used equipment and its location.

Is it possible for a person to install the chiller AC by himself?

It is advisable to have a professional conduct the installation to meet the optimum efficiency and avoid any incidences.

What are some of the frequent problems with chiller AC?

Problems may involve leaking of refrigerants, mineral build-up in water cooled systems, compressor problems.